How Aircraft Magnetos Power Your Engine

- Crossfire Magneto Service

- Jul 28, 2025

- 4 min read

Aircraft magnetos are essential components in many piston-engine aircraft. They provide the spark that ignites the fuel-air mixture in the engine cylinders, enabling the engine to run smoothly and reliably. Understanding how these devices work can help pilots, mechanics, and aviation enthusiasts appreciate the critical role magnetos play in aviation safety and performance.

What Are Aircraft Magnetos and How Do They Work?

Aircraft magnetos are self-contained ignition systems that generate electrical energy to create sparks in the engine's cylinders. Unlike automotive ignition systems, magnetos do not rely on the aircraft's battery or electrical system. Instead, they use the engine's rotation to produce high voltage electricity.

The basic principle behind a magneto is electromagnetic induction. Inside the magneto, a rotating magnet spins near a coil of wire. As the magnet turns, it induces an electric current in the coil. This current is then transformed into a high-voltage spark by the magneto's internal components, including the distributor and spark plug wires.

Each cylinder in the engine has a spark plug connected to the magneto. The magneto distributes the spark to each plug at the precise moment the fuel-air mixture needs ignition. This timing is critical for efficient engine operation and power output.

Key Components of an Aircraft Magneto

Magnet: Rotates to generate magnetic fields.

Coil: Converts magnetic energy into electrical current.

Distributor: Directs the spark to the correct cylinder.

Points and Condenser: Control the timing and duration of the spark.

Because magnetos operate independently of the aircraft's electrical system, they provide a reliable source of ignition even if the battery fails. This redundancy is vital for flight safety.

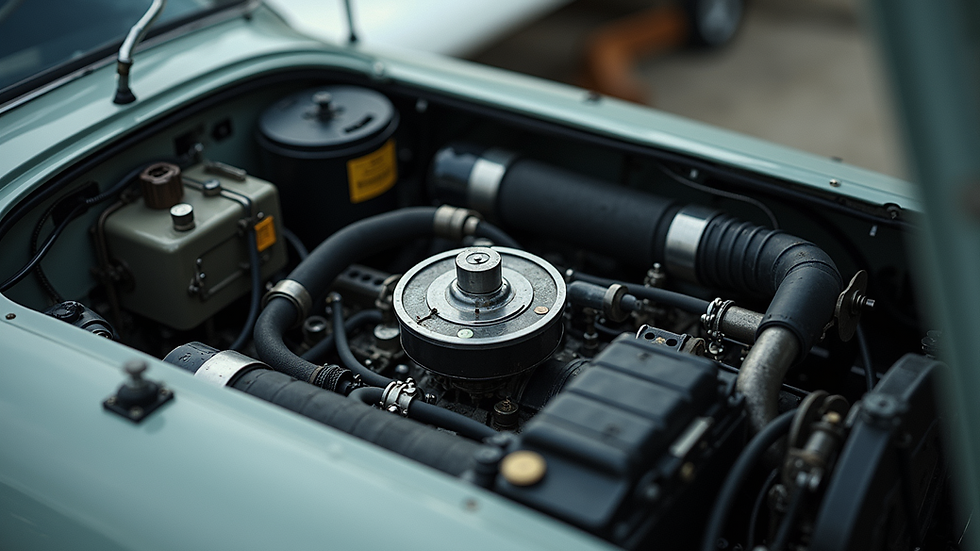

Close-up view of aircraft magneto internal components

The Role of Aircraft Magnetos in Engine Performance

Aircraft magnetos are not just ignition sources; they directly influence engine performance and efficiency. Properly functioning magnetos ensure that the spark occurs at the right time and with sufficient energy to ignite the fuel-air mixture completely.

Dual Magneto Systems

Most piston aircraft engines use dual magnetos for redundancy and improved combustion. Each magneto powers one spark plug per cylinder, resulting in two sparks per cylinder. This dual ignition system offers several benefits:

Improved Combustion: Two sparks ignite the mixture more evenly and quickly.

Increased Power: More complete combustion leads to better engine output.

Safety: If one magneto fails, the other can keep the engine running.

Pilots often perform a magneto check during pre-flight to ensure both magnetos are working correctly. A slight drop in RPM is normal when switching from both magnetos to one, but a significant drop or engine roughness indicates a problem.

Maintenance and Troubleshooting

Magnetos require regular inspection and maintenance to function correctly. Common issues include worn points, cracked coils, or damaged distributor caps. These problems can cause weak or inconsistent sparks, leading to rough engine operation or failure to start.

Using high-quality parts and services, such as those offered by crossfire magneto, can help maintain magneto reliability and extend their service life.

Eye-level view of aircraft engine compartment showing magneto installation

How much is a 500 hour magneto inspection?

A 500-hour magneto inspection is a routine maintenance procedure required by many aviation authorities to ensure magnetos remain in good working condition. The cost of this inspection can vary depending on the service provider, magneto type, and location.

Typical Cost Range

Basic Inspection: $200 to $400 per magneto

Overhaul or Repair: $500 to $1,200 depending on parts and labor

Additional Services: Testing, timing adjustments, and cleaning may add to the cost

What Does the Inspection Include?

Visual inspection for cracks, corrosion, and wear

Testing of coil resistance and spark output

Checking and adjusting timing and point gaps

Cleaning and lubricating moving parts

Replacement of worn components as needed

Recommendations for Owners

Schedule inspections according to the manufacturer's recommendations and regulatory requirements.

Use certified repair stations or experienced mechanics.

Consider investing in a quality overhaul if the magneto shows signs of wear or poor performance.

Regular inspections help prevent in-flight ignition failures and extend the life of your magnetos.

High angle view of aircraft maintenance technician inspecting magneto

Advantages of Using Modern Magneto Technologies

While traditional magnetos have served aviation well for decades, modern technologies have introduced improvements that enhance reliability and performance.

Electronic Ignition Systems

Some aircraft now use electronic ignition systems that replace mechanical points with solid-state components. These systems offer:

More Precise Timing: Electronic controls can adjust spark timing dynamically.

Reduced Maintenance: No mechanical points to wear out.

Improved Fuel Efficiency: Better combustion control.

However, electronic systems often still rely on magnetos or backup magneto systems for redundancy.

Benefits of Upgrading

Increased engine smoothness and power

Lower fuel consumption and emissions

Enhanced reliability and reduced downtime

When considering upgrades, consult with a qualified mechanic to ensure compatibility with your engine and compliance with aviation regulations.

Tips for Maintaining Your Aircraft Magnetos

Proper care and maintenance of magnetos can prevent costly repairs and improve engine reliability. Here are some practical tips:

Regular Inspections: Follow the recommended inspection intervals, typically every 500 hours or annually.

Keep Them Clean: Dirt and moisture can cause corrosion and electrical shorts.

Check Timing: Ensure spark timing is correct for optimal engine performance.

Use Quality Parts: Replace worn components with certified parts.

Store Properly: If removing magnetos, store them in a dry, clean environment.

By following these guidelines, you can maximize the lifespan and effectiveness of your magnetos.

Understanding the Importance of Magnetos in Flight Safety

Magnetos are a critical safety feature in piston-engine aircraft. Because they operate independently of the aircraft's electrical system, they provide a reliable ignition source even if the battery or alternator fails.

In the event of an electrical failure, the engine can continue running on magneto power alone. This redundancy is why magnetos are mandatory in most certified aircraft engines.

Pilots should always perform magneto checks during pre-flight and be familiar with the signs of magneto problems, such as rough running or loss of power when switching magnetos.

Aircraft magnetos are fascinating devices that combine simple electromagnetic principles with precise mechanical engineering to keep aircraft engines running safely and efficiently. Whether you are a pilot, mechanic, or aviation enthusiast, understanding how magnetos work and how to maintain them is essential for reliable flight operations. For those looking for quality magneto services or parts, companies like crossfire magneto offer trusted solutions to keep your engine firing strong.